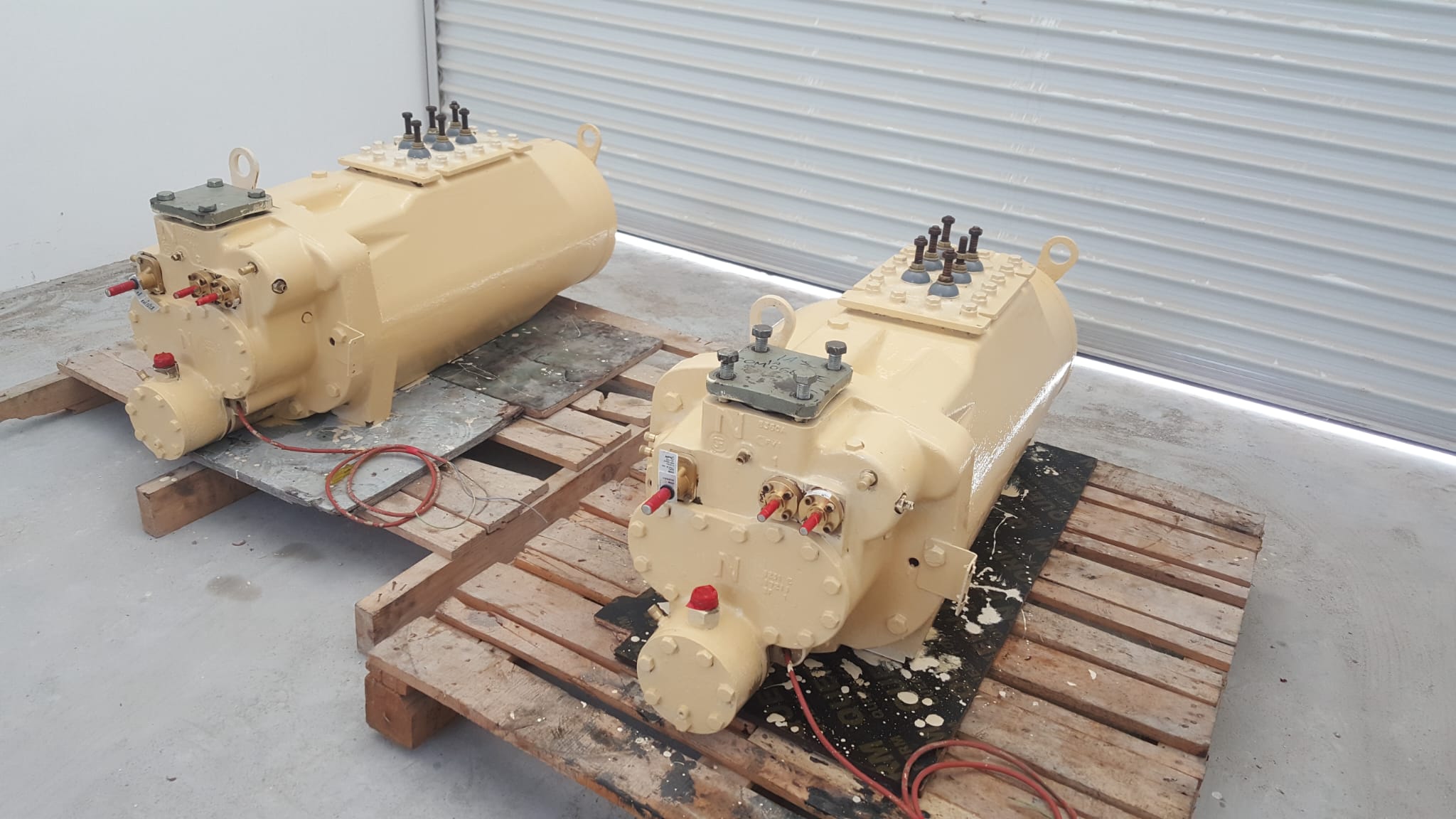

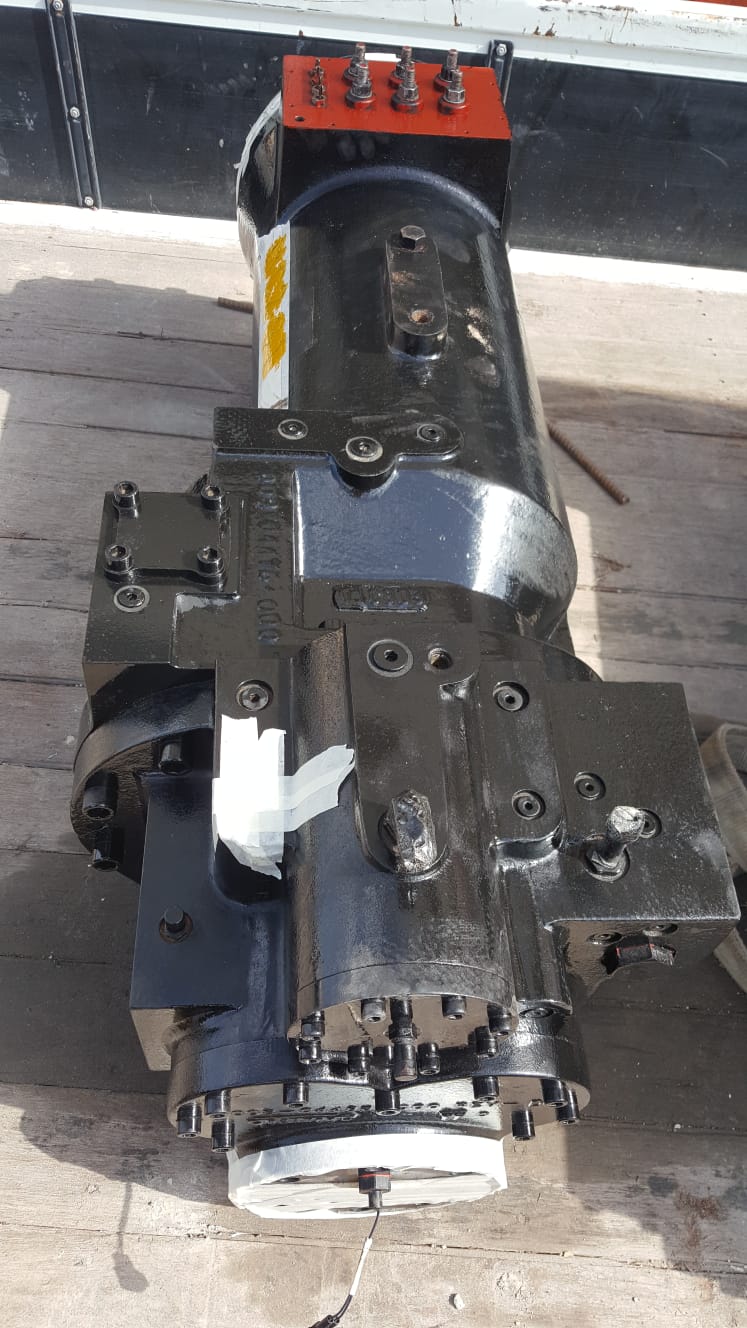

Screw Compressor

Overhaul Screw Compressor

At Refix, our screw compressor overhaul process is designed to restore your equipment to peak performance through a thorough set of maintenance and repair procedures. Screw compressors, which utilize two interlocking helical screws for air or gas compression, are subject to wear and tear over time.

Our comprehensive overhaul includes:

Our overhaul service is typically performed when a compressor shows significant performance issues, after a specified number of operating hours, or as part of a scheduled maintenance program. At Refix, we are committed to extending the lifespan of your equipment and maintaining its efficiency.